Bayesian Optimization for Robust Mo Thin-Film Properties

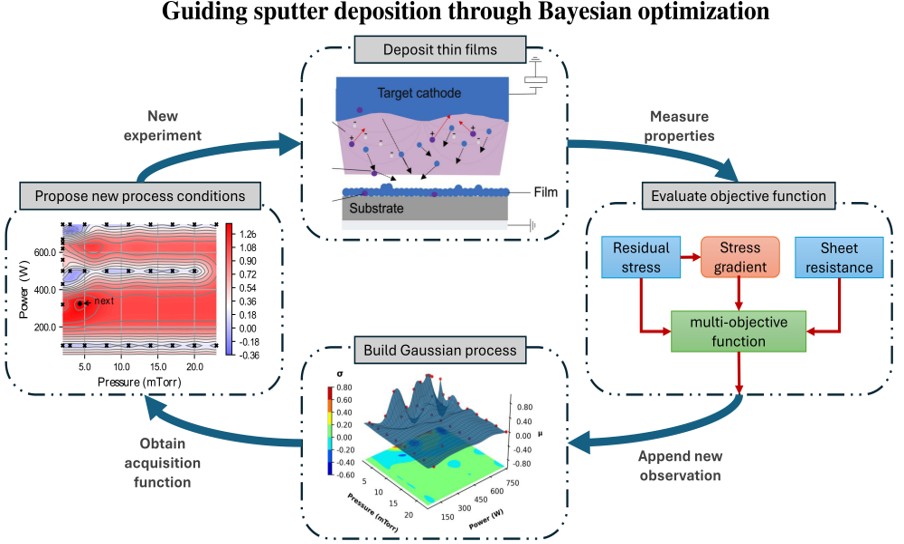

Developed a Bayesian optimization framework to fine-tune sputter deposition process conditions—specifically power and pressure—to achieve target residual stress and sheet resistance in molybdenum (Mo) thin films, while prioritizing robustness against process variability. By incorporating an objective function that balances mean properties and their fluctuations, this method efficiently explores the design space and identifies stable configurations under stochastic process noise

Refer paper (Shrivastava et al., 2024) for details.

For code refer GitHub Repository.

The above plots illustrate the Bayesian optimization landscape used to tune deposition parameters for stable Mo thin-film properties.

-

Mean predictions represent the expected values of properties like residual stress and sheet resistance across the process space.

-

Standard deviation highlights regions with high uncertainty, where the model is less confident.

-

Acquisition function guides the optimizer toward regions that balance exploration and exploitation—targeting areas with both promising outcomes and high uncertainty. Together, these visualizations reveal how the model navigates the trade-off between optimizing material performance and ensuring robustness against process noise.

As shown below, based on the approach, we were able to efficiently identify deposition conditions that yield desirable and stable Mo thin-film properties, such as low residual stress and controlled sheet resistance, even in the presence of process variability. This demonstrates the effectiveness of Bayesian optimization in guiding experimental design for robust materials processing.